6 Technologies for Ultimate Performance

Scodix is dedicated to optimizing quality and productivity both on the production floor and in the production workflow. Six technologies drive the Scodix Ultra presses to achieve maximum output and high-quality print functionality.

Scodix SHD

Scodix Smart High-Definition (SHD) controls the precise placement and drop size of Scodix polymer to surface areas. The algorithms enable precision sharp borders for the finest details designs.

Scodix MLE

Scodix Multi Layer Embellishment (MLE) is the structured layering of the polymer by repeating rotations of the media under the print heads in a single pass. Multiple cycling of the paper path achieves high-efficiency building of tactilie layers, for Scodix Sculturing, Scodix Braille and Scodix Crystal applications.

Scodix AI

Scodix AI through insights gained from databases of embellishment files, identifies the best elements in a CMYK design suited for embellishment layering. From within a web interface, a choice of options is automated. Scodix AI offers print providers the ability to automatically value-up print jobs at the click of a button.

Scodix VDE

Scodix VDE allows for the customization of print enhancements on a variable data basis. With Scodix VDE, users can apply enhancements such as spot UV, foil, embossing, and more to individual elements within a printed piece, making each one stand out and grab the recipient’s attention.

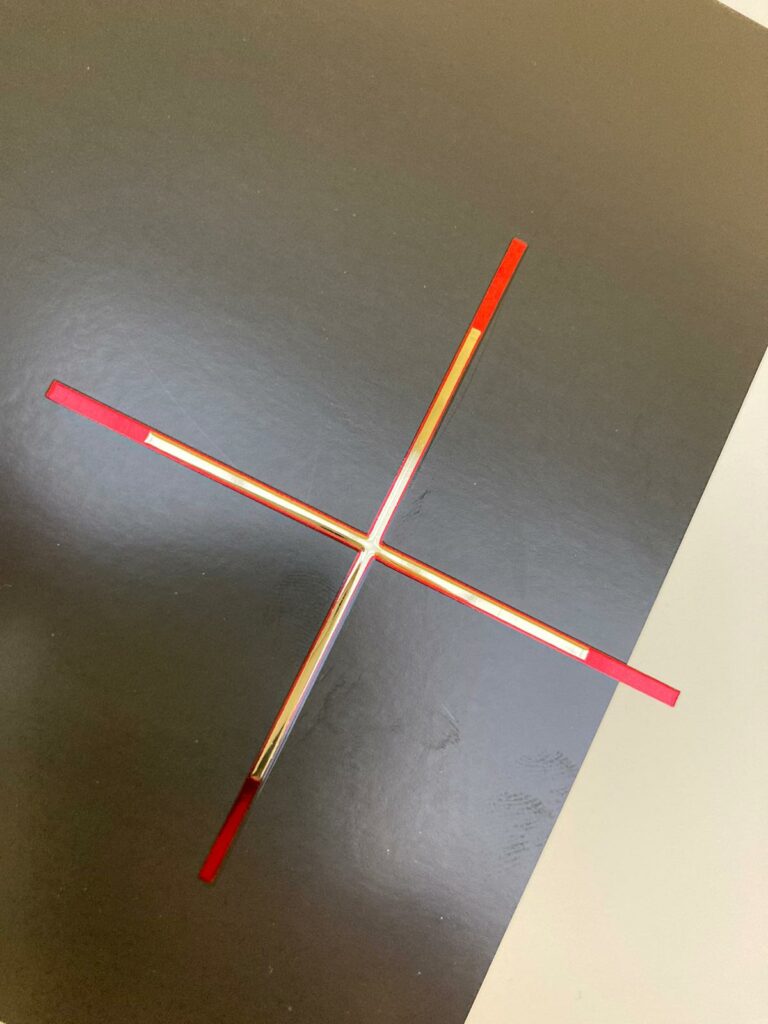

Scodix PAS™

Scodix Pinning Activate and Secure sets the polymer droplets in place on the individual sheets before continuing on the paper path to receive foil and final curing before delivery.